Business Case ROI on the purchase of StemPro Cutters

Your investment in StemPro cutters for your retail floral locations will pay for itself in less than 12 months due to a combination of the following:

CUTTER StemPro

A safe, efficient, high-powered machine designed to optimize your operations.

KEY FACTS Click on each item to reveal the benefits

1. Labor Savings

2. Elimination of Injuries

3. Inefficiencies of wet-pack

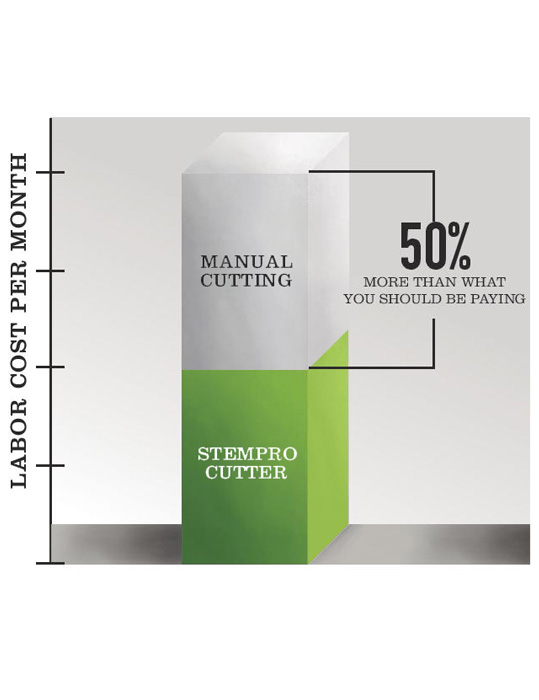

1. Labor Savings

Save over $6.800 in labor costs!

In order for floral product at your retail locations to have maximum life, it must be recut before being placed into the merchandising fixture. According to best practice standards, all product should be recut when it arrives, regardless of wet-pack or dry-pack. Therefore, there is no additional labor cost to receive solely in dry-pack and processing at store level (see below). In fact, labor is reduced because employees no longer have to deal with the collection, reduction and disposal of wet pack shipping materials.

Experience has shown that your floral staff will be able to process flowers at store level in half the time using StemPro cutters compared to manual cutting methods, essentially cutting your labor costs in half.

In the hypothetical situation above, where it takes 10 hours a week to cut flowers and the loaded hourly pay for a floral employee is $18, the average monthly savings in labor costs with StemPro cutters would be $360. On this basis alone, StemPro cutters will pay for themselves in less than 18 months.

2. Elimination of injuries

Keep your workers safer

Major retailers experience an average of two workman's compensation claims annually resulting from injuries in their floral departments. Assuming that the average incident cost is $84,600 (though some are much more), twice a year equals $168,000 a year. This includes both traumatic and repetitive-stress injuries and costs include medical and rehabilitation costs, paid time off, replacement worker training and increased worker’s compensation rates.

Over the seven year expected service life of the StemPro cutters, eliminating injuries and their associated costs will pay for about 200 cutters.

3. Inefficiencies of wet-pack

Reduce your product cost with this simple change

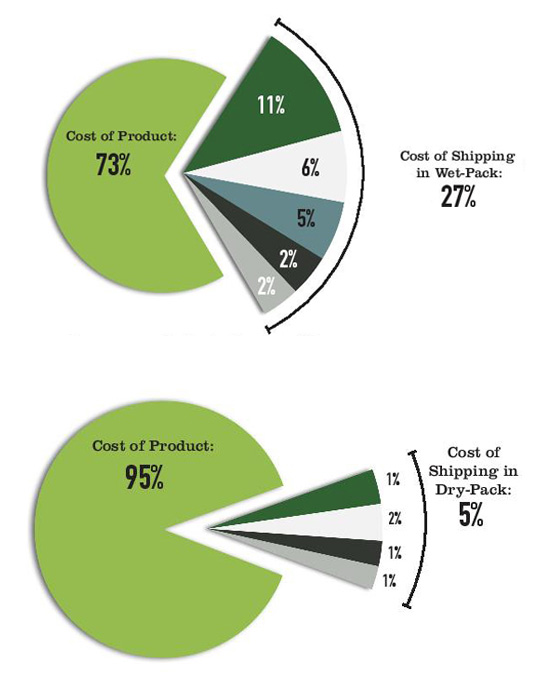

With StemPro cutters, you can receive in dry-pack and reduce costs. If you are currently receiving at store level in wet pack, you are paying a 22% premium for your floral product when compared to receiving at store level in dry pack.

By switching to dry-pack, you can eliminate the cost of:

1. Additional transportation associated with trucking water,

2. Wet-pack packaging (corrugated box, plastic box liner, plastic bucket),

3. Product loss from incorrect handling/packaging failure, and

4. Inefficiencies of storage at distribution centers (see below). The blue 5% represents the labor of cutting and repacking at processing centers a step that is completely eliminated with dry-pack.

StemPro cutters help employees efficiently cut at the store level, giving you the opportunity to reduce costs.

StemPro vs. Other Cutters

Improvement (in % by item)

4. Extending Flower life

5. Preservation of Stem length

6. Avoid cross-contamination

4. Extending Flower life

Increase customer value

When purchasing a floral product, an item that’s already highly perishable, longevity is key. The longer the flowers last, the happier the customer is, and the more likely they’ll come back to your establishment for another floral purchase. Dry-pack allows for the flowers to get their first fresh cut at the store level (instead of at distribution), so your customers can enjoy dramatically longer lasting flowers.

5. Preservation of Stem length

Be consistent with your cut

Most retailers have exacting and specific quality metrics for their floral product, including expectations about stem length. However, you have no control or consistency about how much stem end is removed during processing at store level. If you specify 60 cm roses and store employees are cutting off 4-6” at the store, clearly value is lost and dollars wasted.

The StemPro cutter removes a consistent ¾” of stem length with each cut. Cutting off less than ¾” may not remove all the blockage to hydration, removing more than ¾” offers no additional benefit and wastes stem length.

By preserving the value of your investment in premium floral stock, StemPro cutters save thousands at each retail location.

6. Avoid cross-contamination

Protect your product with every cut

Sanitation in manual cutting is almost impossible, as you cannot practically sanitize the tool between every cut. StemPro cutters have a built-in sanitizing system that wipes the cutting blade with a sanitizing and disinfecting solution (FloraLife® DCD) with every stroke.

This prevents cross-contamination between bouquets.

7. Three times the space

8. The cleanest cut

9. Summary

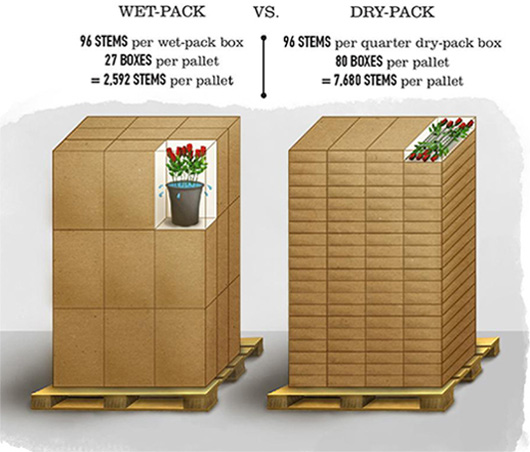

7. Three times the space

Optimize every aspect of your business

Dry-pack is more efficient in terms of transportation, storage, and handling costs. It takes three trucks to carry in wet-pack what one truck can carry in dry-pack. In other words, wet-pack takes up 3 times the space in your distribution centers. Plus, it is cumbersome and inefficient to lift/handle for the D.C.’s order pickers.

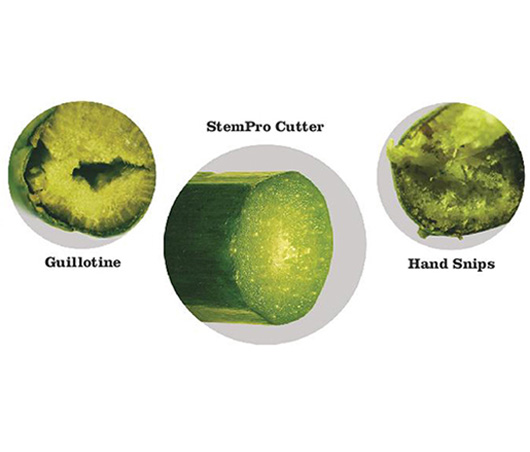

8. The cleanest cut

Cut quality matters

Most retailers find that switching to reliable, safe, consistent cutting with StemPro cutters extends flower life for most varieties by one to two days (including roses). A sharp, clean cut makes your flowers hydrate better and last longer. It reduces shrink resulting from unsold product, which increases profits and gives your customers a better value. The impact of reducing shrink alone could save you tens of thousands of dollars annually at each location.

9. Summary

Reduce your product cost with this simple change

Your investment in StemPro cutters for your retail floral locations will pay for itself in less than 12 months due to a combination of the following:

1. Reduce labor costs2. Eliminate injuries

3. Eliminate packaging waste

4. Extend floral product life

4. Preserve your stem length investment

Together these factors ensure a quick return on your StemPro Cutter investment and will keep your floral department on the “cutting edge” of best practices and efficient operations.

© Copyright 2019 - StemPro Systems, Ltd. - All rights reserved.

Design by Visualatin